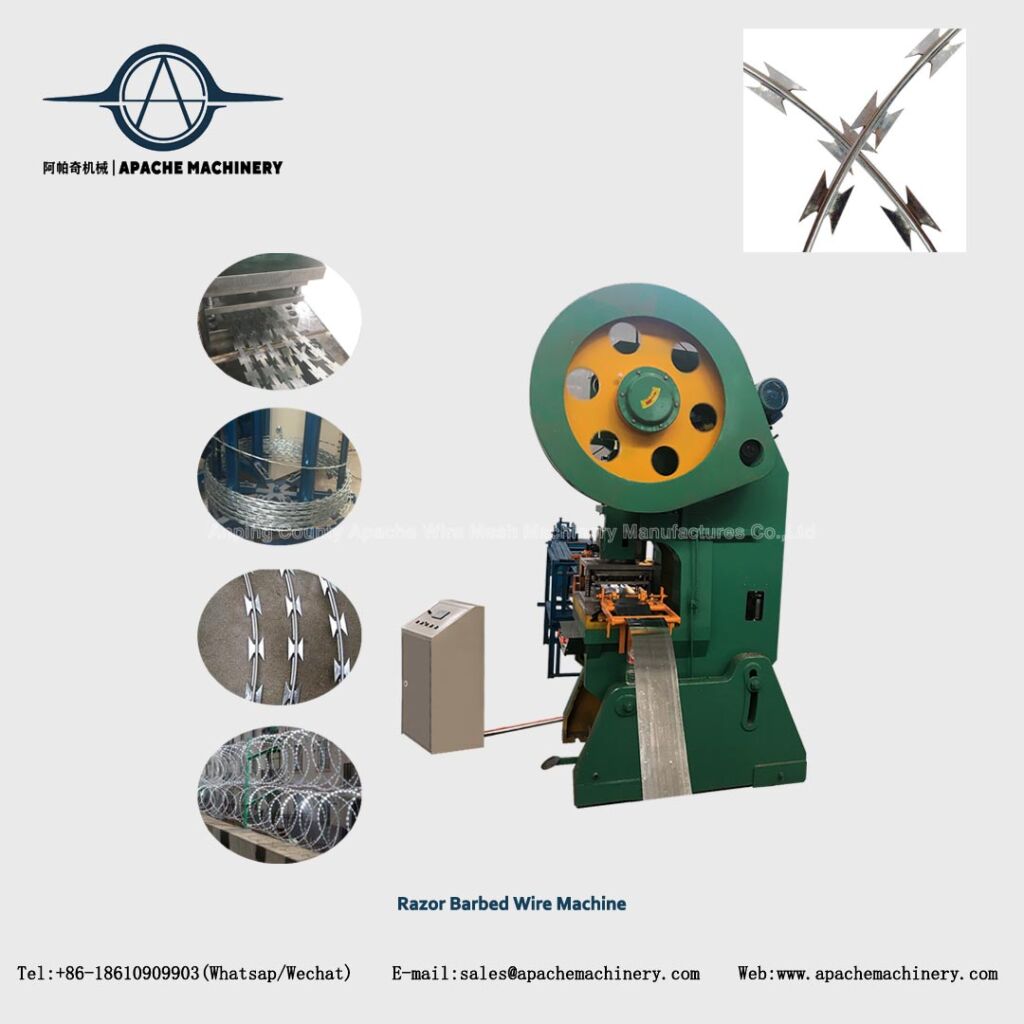

The machine is mainly divided into punching part and wrapping part and suitable for the mass production of various specifications of razor barbed wire.The machine has the advantages of compact structure, simple operation, low energy consumption and easy maintenance.

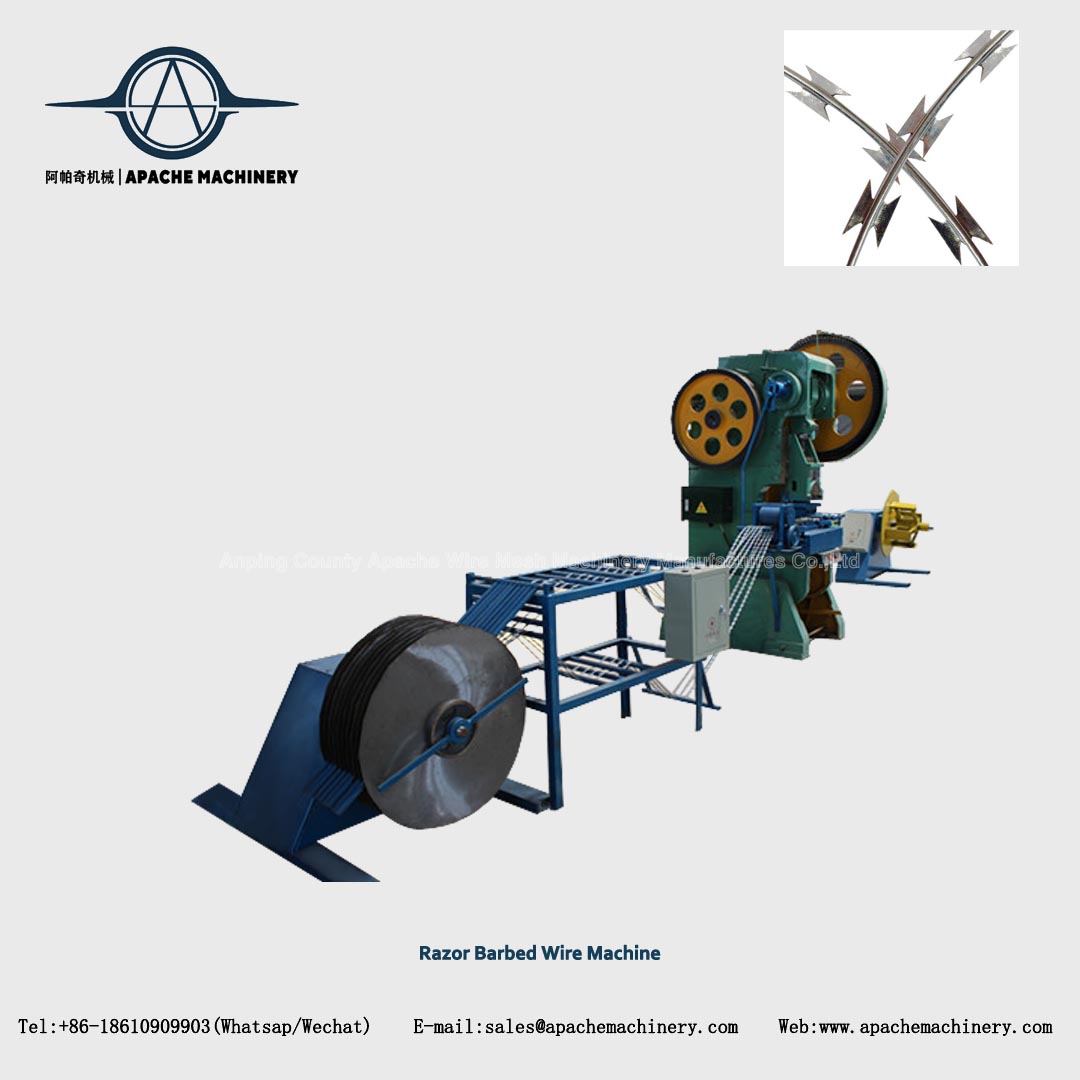

The punch part is mainly composed of feeding machine, punch and receiving machine.The tonnage of the punch depends on the width of the plate.The larger the width of the steel plate is, the more strips can be punched, and the larger the tonnage of the punch is needed.

The wire wrapping part is to wrap the steel wire and barbed sheet together and make the required circular long razor barbed wire.This machine is multi-purpose.After adjustment, it can produce BTO- 10, BTO-11, BTO-12, BTO-18, BTO-22, BTO-25, BTO-30, CBT-60, CBT-65 and other types of razor barbed wire.